| No. | Equipment name | Type | Equipment founction unit:mm |

| 1 | Gantry submerged arc

welding machine | LHA | Gantry height 1850 gauge

4000,welding speed 150-1000/min |

| 2 |

Double cantilever type welding machine

| LHA(2pcs) | For workpiece length

4000-15000.web plate height 200-2200

flange width 200-800.flange thickness8-60.welding speed 240-2400/min |

|

| 3 | Blasting machine | HP8016B | section width 800 height 1600

length 3000-12000(components) |

| 4 | Biger blasting machine | HT1225 type | section width 1300 height 2500 length3000-20000(components) |

| 5 | H-beam assembling machine

| Z25 | for H beam dimension:Flange 200-800thickness6-60 web height 200-2500 web thickness 6-40 |

|

| 6 | H-beam assembling machine

| HZJ15 type | for H beam dimension:Flange 200-800

thickness6-40 web height 200-1500

web thickness 6-32 |

|

| 7 |

H-beam straightening machine

| J600 type | for modify flange thickness≤20 width 150-600

web height〉160 |

| 8 | H-beam straightening machine

| YTJ-60B | for modify flange thickness≤60

width 200~800,

web plate thickness ≤50,

the componets material tensile strength o.s≤600MPa

|

|

| 9 | C steel molding machine

| WH250 type | processing thickness 0.5-3

max width 410.

C beam section dimension 80*50,100*50 |

|

| 10 | Z type of cold bending

steel forming machine

| YXOOKY-72/92-

120/300 | the max processiong thickness3.Z beam section dimension: YXOOKY180-70-65.200-70-65 |

|

| 11 | plate shearing machine | Q11-13*2500 | For the max shearing thickness: 13 max width: 2500 Sheet metal tensile strength

<50n/mm2 |

| 12 | QC11Y-20*2500 | the max cutting thickness20 width: 2500 Sheet metal tensile strength 450-650n/mm2 |

| 13 | universal radial drilling machine | Z3050X16(1) type | the max drilling diameter Φ50,we have other 2universal radial drilling machine can drill Φ32. |

| 14 | Numerical control plate drilling machine

| CDMP2012 | The thickness of the clamp

15-80 Max drill Φ50 the max components dimension 1200*2000 |

| 15 | bending machine | WE67Y-100T/5000 | the max width 5000 max thickness 14 |

| 16 | multi burner cutting machine | CG1-4000A | for cutting length 3300 width 15500 |

| 17 | Color plate pressure plate

forming unit | YX15-255-900 | thickness 1.0 width1000 length 900 |

| 18 | Color plate pressure plate

forming unit | YX-18-250-820 | thickness 1.0 width1000 length 820 |

| 19 | Color plate pressure plate

forming unit | YXOOKM51-380-760 | thickness 1.0 width1000 length 760 |

| 20 | Computer control corlor sheet processing unit

| YX75-200-600 | thickness 1.0 width1000 length 600 |

| 21 | Color plate pressure plate

forming unit | YX51-471 | thickness 1.0 width600 length 460 |

| 22 |

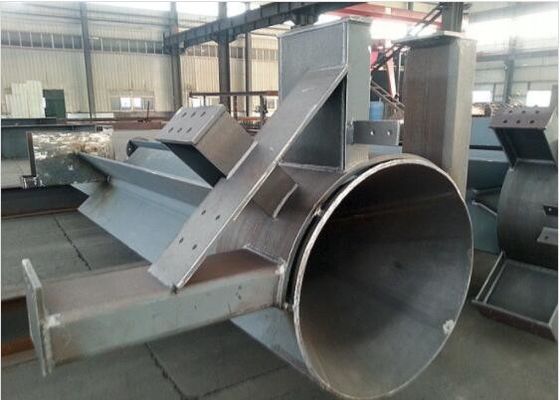

Curve nc pipe cutting machine

| BCNCG-1500VI | diameter Φ60-800 length 550-12000

thickness5-50 |

| 23 | Small CNC cutting machine

| HNC-2100 | for max length 2300 width 2100

thickness 5-150 |

| 24 | portal crane | LD-10T,LD-20T | 10tons and 20 tons, lifting height: 9m |

| 25 | Semi gantry crane

| LD-5T | 15pcs, 5 tons, lifting height: 6m |

| 26 | single-girder crane | LD-3T,LD-5T | 5pcs, 3tons and 5 tons, lifting height: 6m |

| 27 | single-girder crane | LD-3T,LD-5T | 3ton 1pc; 5ton 1pc lifting height:9M |

| 28 | forklift | CPCD50H | lifting weight : 5T height: 3M, |

| 29 | forklift | CPCD30H | lifting weight :3T height: 3M, |

| 30 | gas welding machine | KR500 | 11 pcs |

| 31 | steel tube

processing line | (welded tube)

HG76 | size: 40*80,100*100,120*80 |

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!